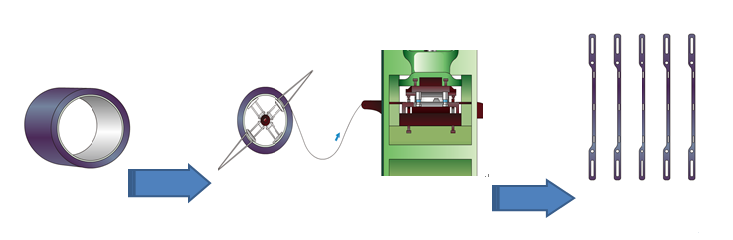

Heddles are important components of the weaving machines. The most common heddles utilize metallic thin slices which are made through compressing and polishing procedures. Heddles have long been made using stainless steel as the element of the raw material. In recent years, there have been great breakthroughs in terms of the materials used, after long process of R&D, plastic heddles have been created to replace stainless heddles. The majority of the injected and soldered plastic heddles that are currently encountered in the market often use very cheap plastics as raw materials which can be problematic during the weaving process, resulting in poor quality in the greige.

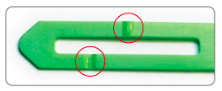

On the contrary, we use raw materials that are rigorously selected and our products are manufactured under strict supervision during the manufacturing process. Quality inspection for our products before the delivery also follow rigid resulting in high premium quality and stability for our heddles reducing the probability for damage of the plastic heddles, substantially lowering the defects caused by filament scrapes, filament damage or the stickiness between the heddles due to heavy size used. Thus, we managed to upgrade the quality of the greige woven by the plastic heddles and increased weaving productivity and efficiency at the same time which further lead to cost reduction.

QMH Plastic Heddles

QMH plastic heddle (heald) is designed for high speed jet loom with slider heddle frames. It is suitable for use with fine monofilament and multifilament yarns (Nylon, Polyester & etc.) and other synthetic fibers in 10-150 denier ranges.

| (1) When you replace heddles, please keep the surface flat, smooth, so that the heddle could slide freely. |

| (2) The tip of the plastic heddle assembly above the round for the bottom |

| (3) Chemical fiber denier is generally no more than the 250D. |

| (4) Weaving density suggestion: less than 210T - 4 heddle frames; over 210T - 6 heddle frame. |

| (5) The cleaning method is similar to stainless steel heddles, without heating or exposure. |

|

(6) Do not scrub with a wire brush.

|

| (2) Super light : weighs only 25% of stainless steel heddle's weight. |

| (3) Green products : Save about 3% of energy consumption.Same as the stainless heddles,plastic heedles can also be recycled. |

| (4) Easy to handle, easy to replace and easy to clean. |

| (5) Enabling a higher RPM for optimal production efficiency. |

|

(6) Better noise reduction designed for providing employees a better working environment at textile plants.

|